Toolpath, simulation and post processing support for sub-spindles.

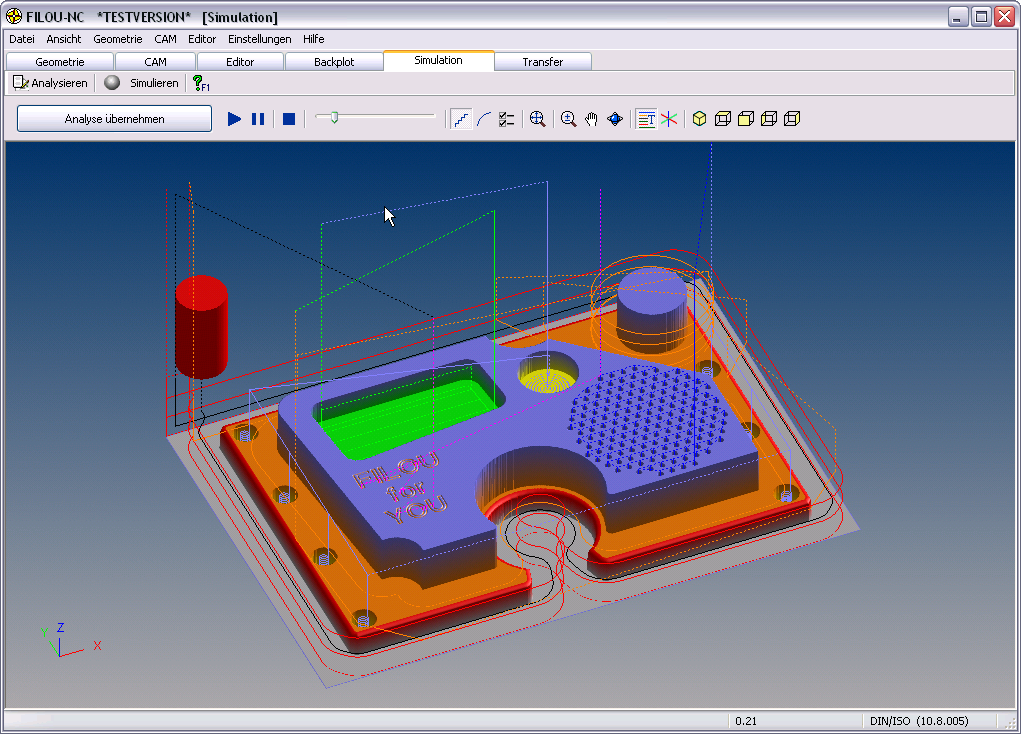

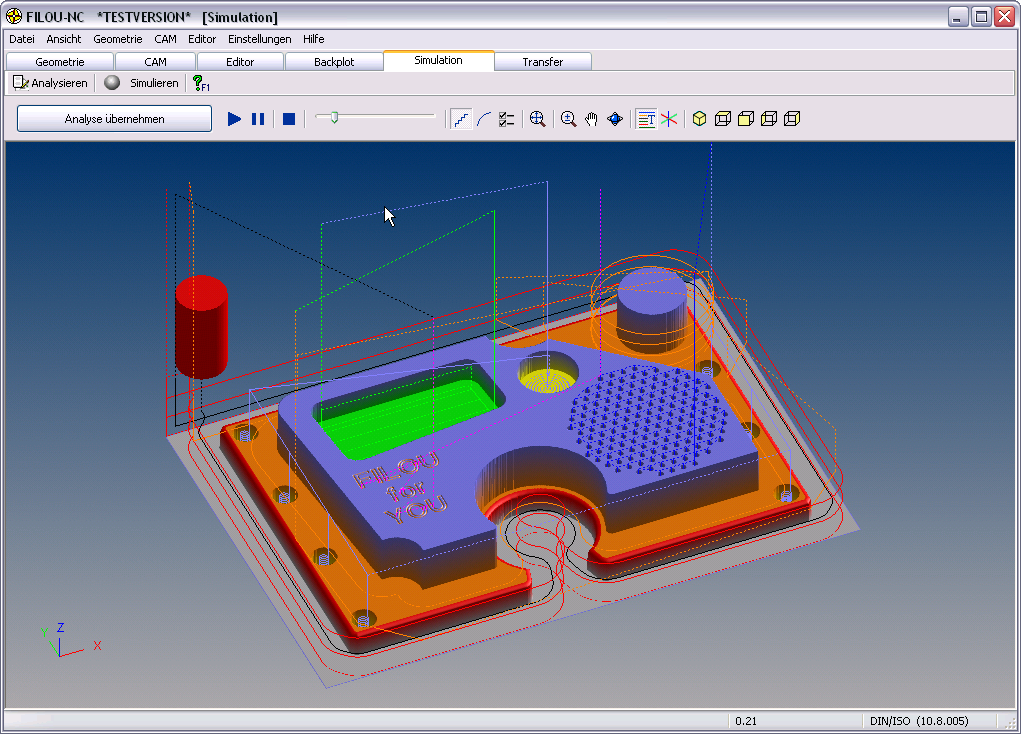

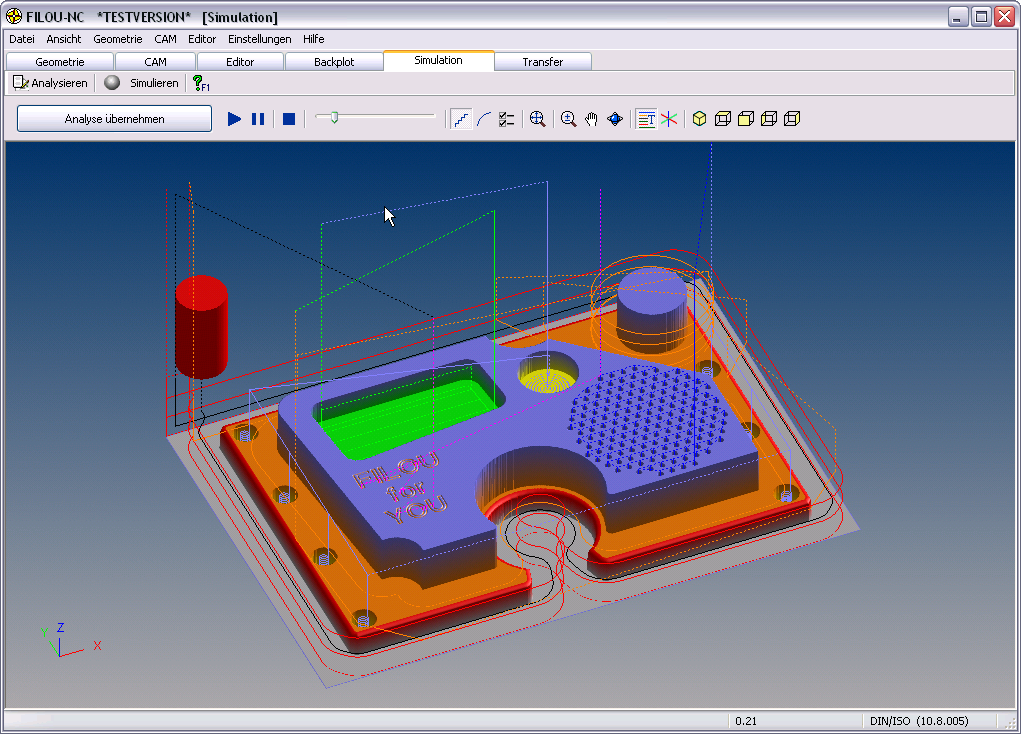

Simulated stock shape can be saved as an STL file for use as Turn, Mill-Turn, Mill or Wire EDM stock shapes. Define chuck to use for toolpath simulation. Work in process (WIP) monitoring of stock increases cutting efficiency. Define stock as bar stock, a revolved sketch, a 2D WIP sketch or from an STL file. Machining algorithms use the latest toolpath and gouge protection methods. CAMWorks provides an Interactive Turn Feature wizard for defining features that need to be defined for your facility’s machining requirements, such as custom OD and ID grooves.ĬAMWorks Turning provides fast, error-free cutting using standard inserts for both front and rear turret configurations and toolpath, simulation and post processing support for sub-spindles.

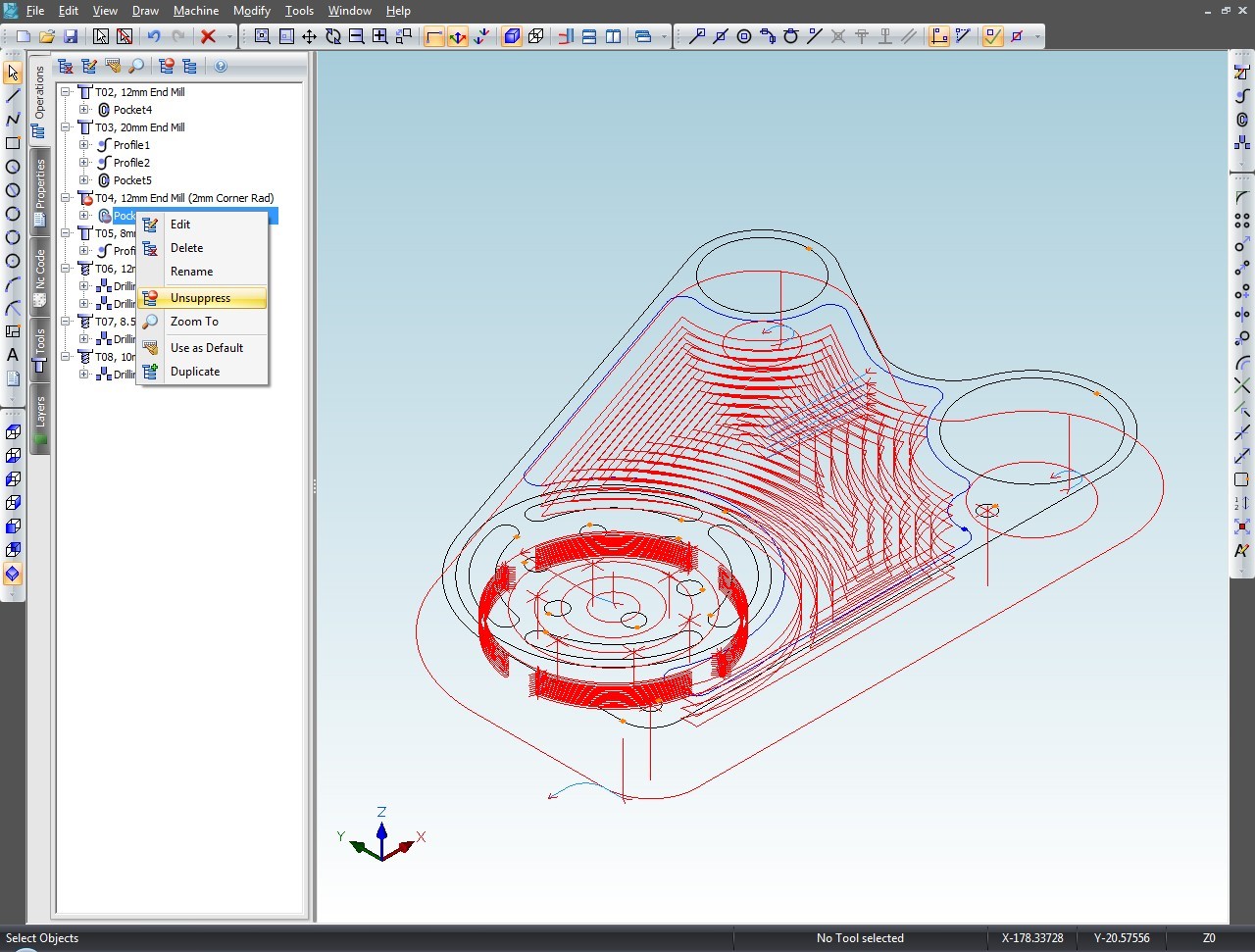

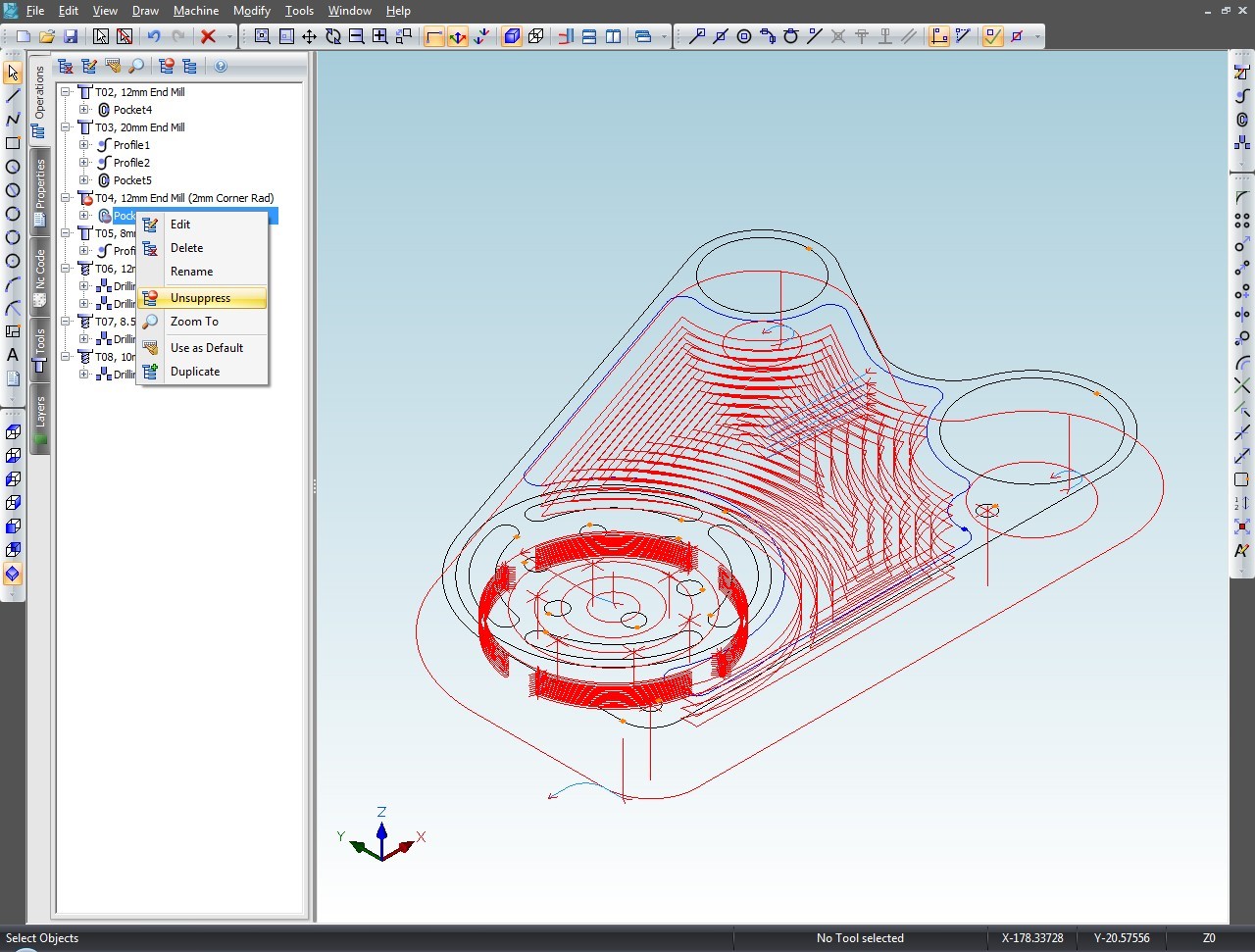

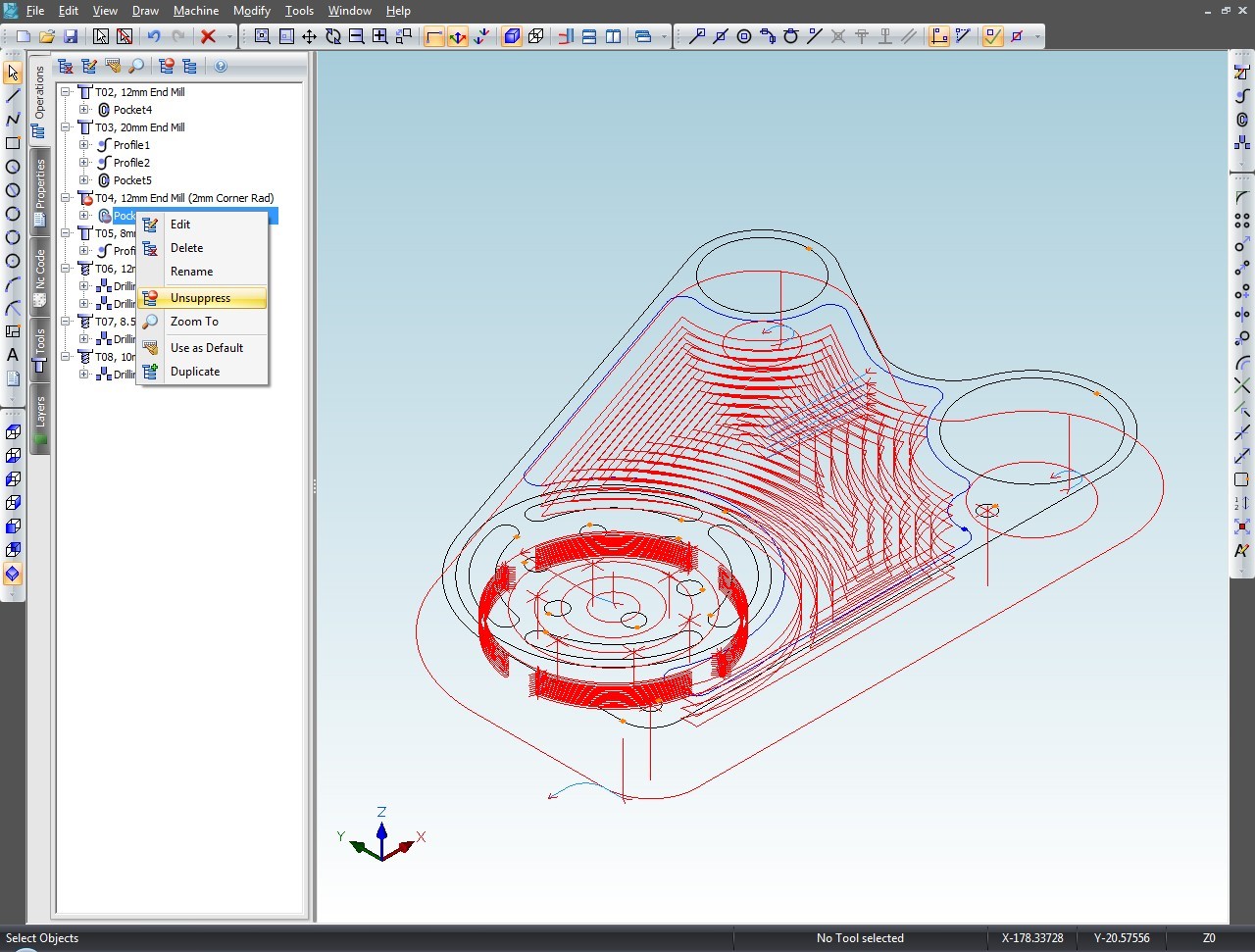

Simulated stock shape can be saved as an STL file for use as Turn, Mill-Turn, Mill or Wire EDM stock shapes. Define chuck to use for toolpath simulation. Work in process (WIP) monitoring of stock increases cutting efficiency. Define stock as bar stock, a revolved sketch, a 2D WIP sketch or from an STL file. Machining algorithms use the latest toolpath and gouge protection methods. CAMWorks provides an Interactive Turn Feature wizard for defining features that need to be defined for your facility’s machining requirements, such as custom OD and ID grooves.ĬAMWorks Turning provides fast, error-free cutting using standard inserts for both front and rear turret configurations and toolpath, simulation and post processing support for sub-spindles.  When bar stock is used, AFR generates a cutoff feature on the opposite side of the face feature. AFR recognizes features on native solid models or on solid parts imported via IGES, SAT, etc. CAMWorks, incorporates Machining Intelligence for Automation, a suite of tools that automate Feature Recognition and the generation of toolpaths based on a user-defined technology database.Īutomatic and Interactive Feature RecognitionĪutomatic Feature Recognition (AFR) analyzes the part shape and defines the most common machinable features such as the OD and ID of the part, front face and grooves. CAMWorks 2 and 4 Axis Turning software for programming CNC lathe machines includes automatic roughing, finishing, grooving, threading, cutoff and single point (drilling, boring, reaming and tapping) cycles.

When bar stock is used, AFR generates a cutoff feature on the opposite side of the face feature. AFR recognizes features on native solid models or on solid parts imported via IGES, SAT, etc. CAMWorks, incorporates Machining Intelligence for Automation, a suite of tools that automate Feature Recognition and the generation of toolpaths based on a user-defined technology database.Īutomatic and Interactive Feature RecognitionĪutomatic Feature Recognition (AFR) analyzes the part shape and defines the most common machinable features such as the OD and ID of the part, front face and grooves. CAMWorks 2 and 4 Axis Turning software for programming CNC lathe machines includes automatic roughing, finishing, grooving, threading, cutoff and single point (drilling, boring, reaming and tapping) cycles.